Overview

We are building stable processes for global automotive parts supply chains.

Beyond sustainable logistics,

embedding customer value in NPC.

As a strategic partner in the global automotive parts supply chain,

Global SCM designs optimal logistics containers and efficient operational processes

that meet customer requirements, simultaneously improving cost competitiveness

and packaging quality.

Furthermore, we actively support our customers' ESG (Environmental, Social, Governance) management practices to achieve Zero Waste.

Key Packaging

Solutions

Service Process

Feasibility

Assessment

Feasibility Assessment

01 Analysis of Returnable Application Feasibility

02 Evaluation of Operational Sustainability

03 Analysis of Business Risk Factors

Customized

Packaging

Design

Customized Packaging Design

01 Consultation on Packaging Materials and Specifications

02 Unit Container Design

03 Operational Simulation

Cost

Efficiency

Analysis

Cost Efficiency Analysis

01 Cost Reduction Effect Simulation

02 Proposal of Rental Models

On-Site

Verification

Test

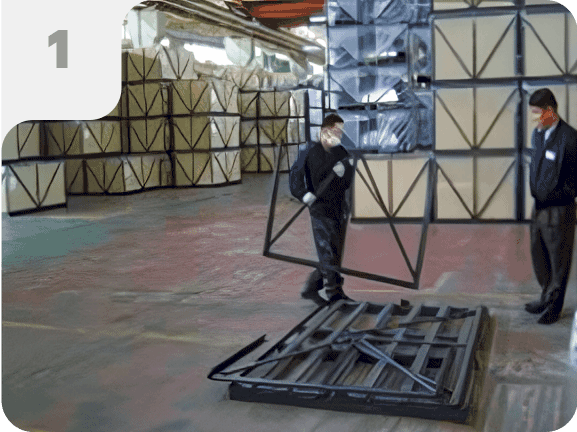

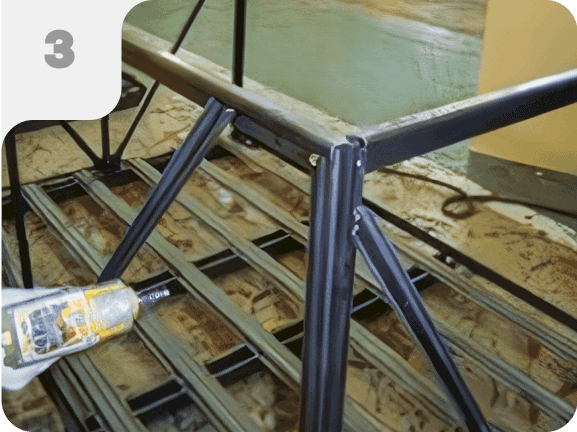

On-Site Verification Test

01 Shock and Load Simulation Test

02 Demonstration of Inbound/Return Process

03 Final Specification Confirmation

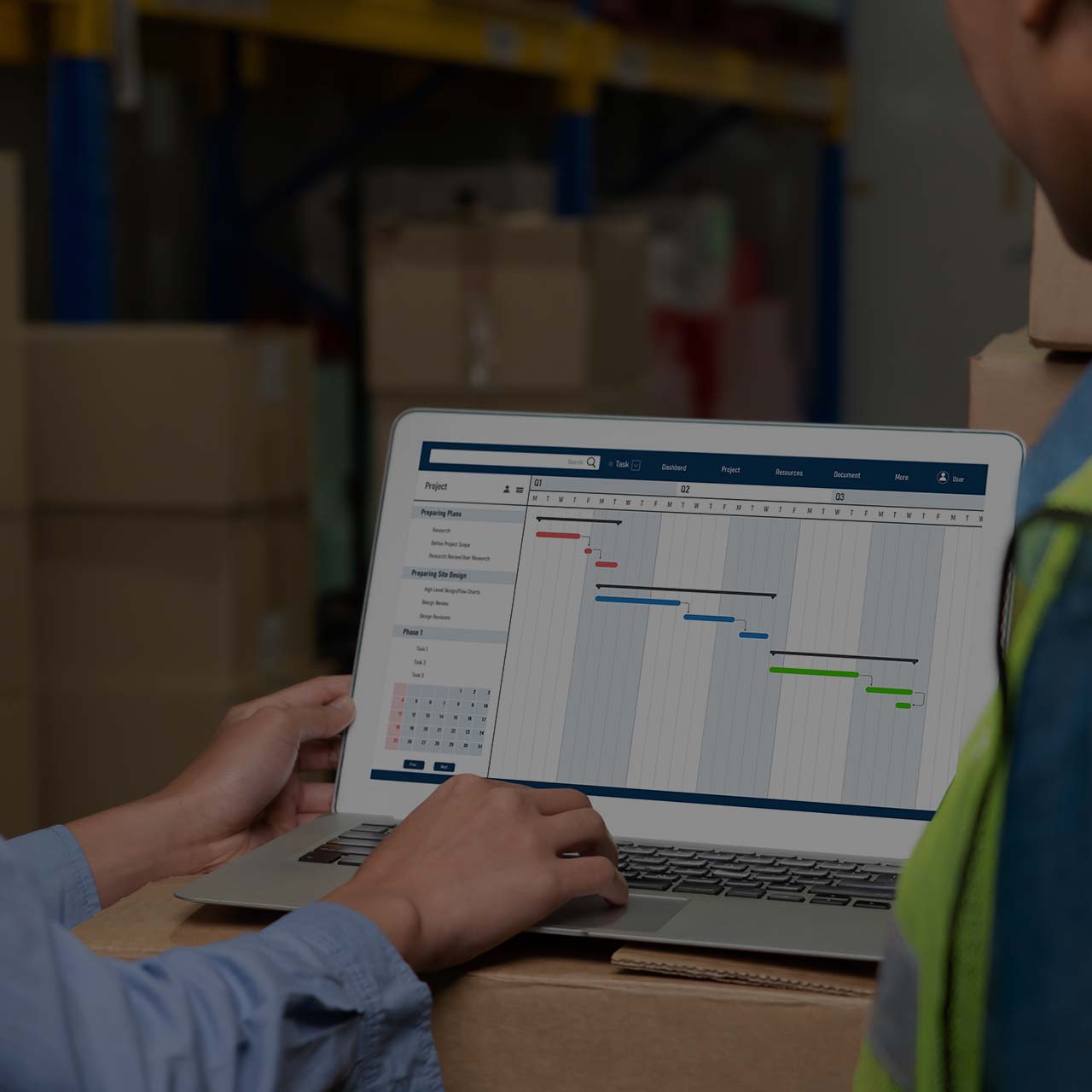

Step-by-Step

Execution

Plan

Step-by-Step Execution Plan

01 Establishment of Reusable and Disposable Scenarios

02 Detailed Timeline Consultation

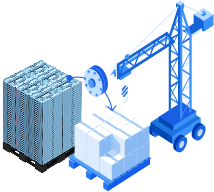

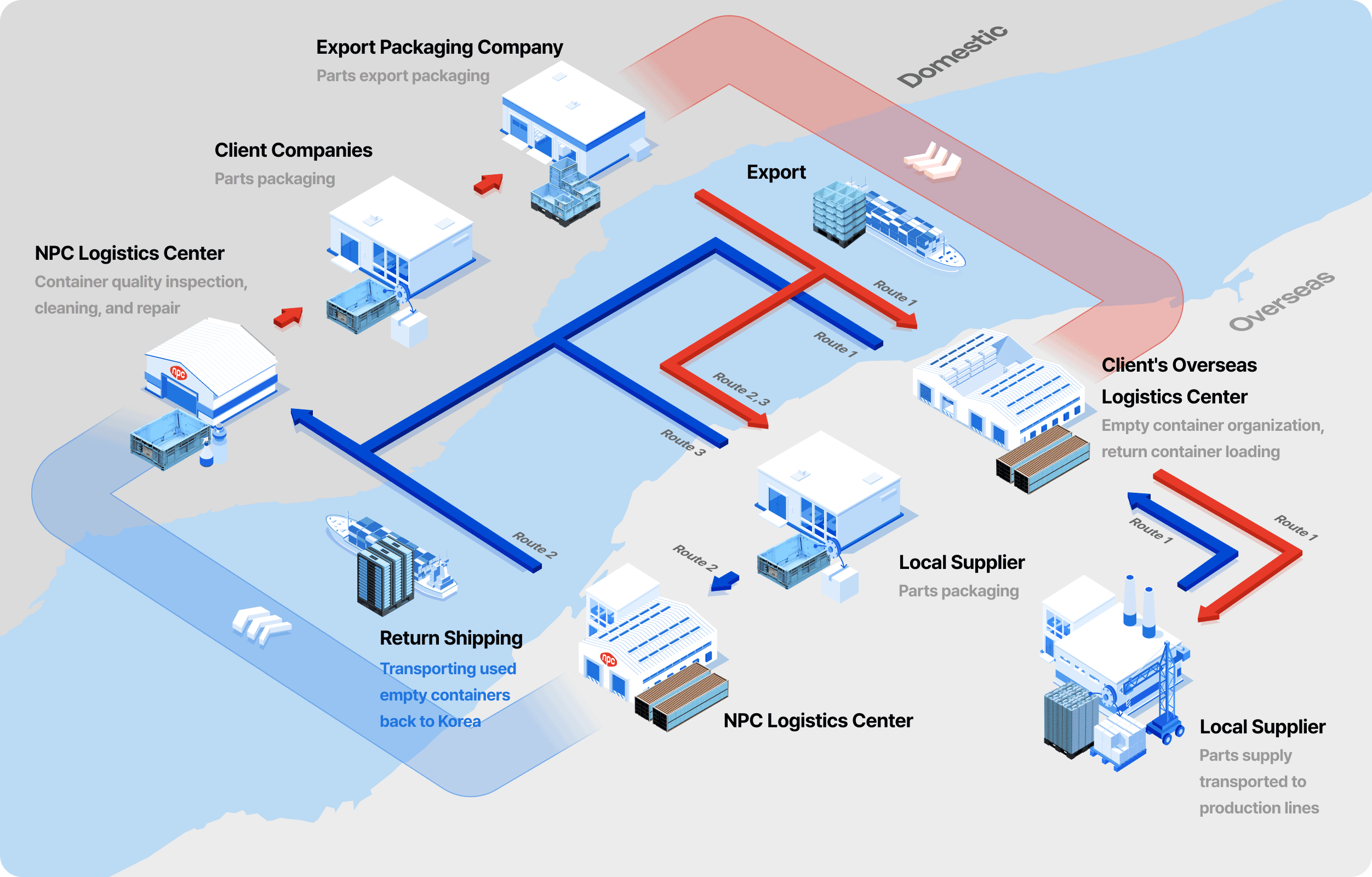

Operational Process

NPC Logistics Center

Container quality inspection,

cleaning, and repair

Client Companies

Parts packaging

Export Packaging Company

Parts export packaging

Export

Client's Overseas Logistics Center

Empty container organization, return container loading

Local Supplier

Parts packaging

Overseas Factory

Parts supply transported to production lines

NPC Logistics Center

Return Shipping

Transporting used

empty containers

back to Korea

Advantages of the Returnable System

Packaging Cost Reduction

Through ULS (Unit Load System) operations based on standard logistics equipment, transportation is possible in the original

packaging unit,

reducing waste elements from product transshipment, transfer, repackaging, and packaging waste disposal,

ultimately resulting in

reduced transportation and packaging costs throughout the entire supply chain.

Total Cost

Management

Standard One-Way Packaging

Repeated packaging material purchases

Excessive use of inner packaging materials

Separate purchase of process boxes

Unpacking, transfer, and repackaging occur

The packaging material assembly and disassembly process required

High labor hours

Difficulty in mutual stacking

Reduced container fill rate

Unused space occurs

Insufficient rigidity →

Limited stacking capability →

Occupies more storage space →

Increases storage costs

Weak packaging strength

Vulnerable to external conditions like vibration and moisture

Possibility of damage during repackaging

Large amount of packaging waste generated

Organization/storage space required

Processing labor and costs incurred

Use of low-strength packaging materials leads to part damage claims and supply disruptions.

VS

Packaging Material Cost

Labor Cost

Transportation Cost

Storage Cost

Quality Cost

Waste Storage and Processing Cost

Claim Cost

NPC Multi-Way Packaging

Packaging material rental use (no investment cost)

Minimized inner packaging materials

No need for process boxes

No unpacking, transfer, or repackaging with optimized design

Ready to use without packaging material assembly and disassembly

Minimized labor hours

Easy mutual stacking with standardized structure

Improved container fill rate

Minimized unused space

Excellent rigidity

and durability →

Enables stable

multi-layer stacking →

Improves storage efficiency →

Reduces storage costs

Excellent packaging strength

Superior external environment resistance

No repackaging

No waste generation

Reduced work/storage space

No processing costs

Use of high-strength, reusable packaging minimizes claim costs and enhances supply stability.

Packaging Strength

Packaging materials designed with high-strength materials and structures experience minimal deformation even with repeated use,

making them ideal for long transportation processes and superior product protection. This reduces damage claims and prevents inventory loss.

One-way Packaging Materials

NPC Multi-Way Packaging Materials

Transportation Stability

Designed with structural stability and secure fastening in mind, our packaging prevents shaking or falling accidents during transportation.

As a result, damage claims and product loss rates are reduced, while transportation safety and quality reliability are simultaneously improved.

Inside the Container

One-way Packaging Materials

NPC Multi-Way Packaging Materials

Handling Convenience

Compared to conventional single-use packaging, returnable packaging simplifies work processes, significantly reducing packaging and unpacking time and labor requirements.

The ready-to-use structure without assembly enhances work efficiency, reduces M/H (Man Hours), and boosts on-site productivity.

One-way Packaging Materials

Figures may vary depending on work environment, worker skill level, etc.

Component (Single-Use) Transport

Same Method

1-Side, 2-Side Assembly (Bolt Usage)

4 min × 2 workers

3-Side Assembly

3 min × 2 workers

3-Side Assembly and Packaging

Same Method

4-Side Assembly Completion

Same Method

NPC Multi-Way Packaging Materials

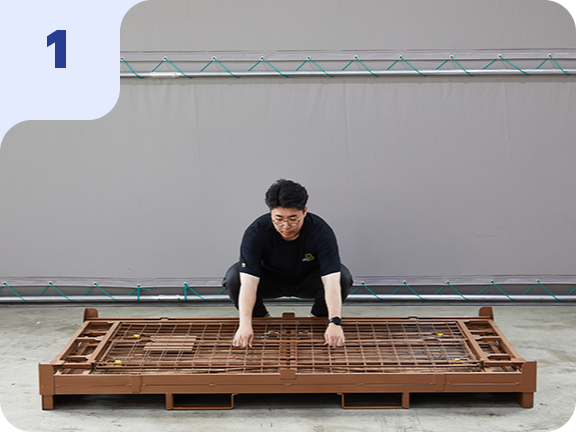

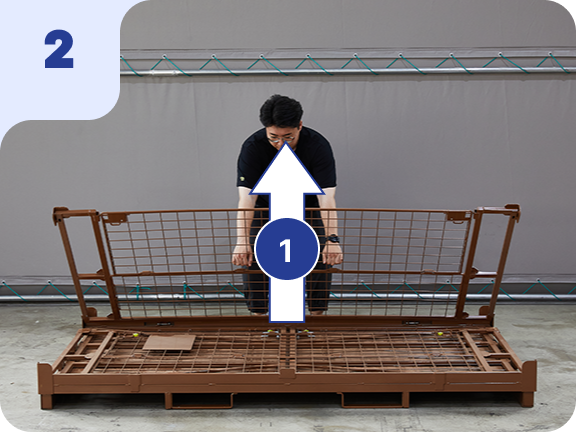

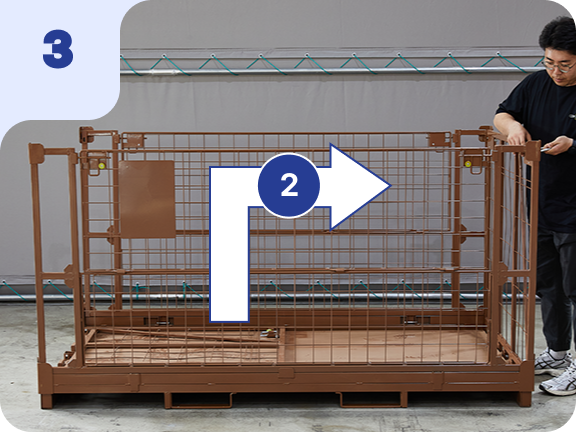

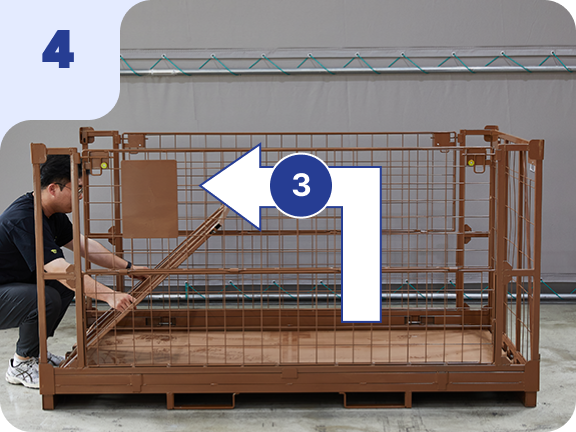

RSB Transport

Same Method

Side Panel Deployment (1 Worker)

1 min × 1 worker

3-Side Deployment

30 sec × 1 worker

4-Side Expansion

1 min 30 sec × 1 worker

RSB Assembly Completion

Same Method

RSB: Returnable Steel Box